我们都知道,目前3D打印用于制造小型的塑料部件很有效,不仅实用,节约了大量时间和成本,并且方便不断的调整原型和修改方案。

希腊Satnogs项目正在开发一个开放源代码的卫星网络地面站。通过这个地面站,团队已经能够与数以百颗的卫星进行通信和实时跟踪。

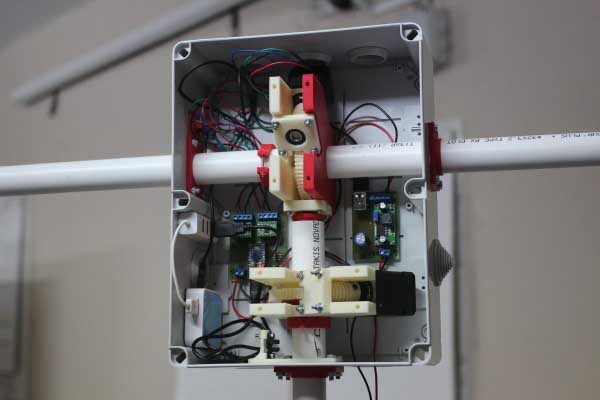

这个项目一开始作为美国宇航局“2014国际空间应用挑战”活动的一部分,全世界有几十个项目参加,其中就包括了来自雅典的Satnogs团队。 Satnogs参加了在虚拟地面站的应用挑战,他们的挑战就是“开发一个通用的天线盒、方向和一个应用程序,可以接收来自轨道上运行的卫星发送到世界各地的信息,创造这些信息的全球数据网络的数据库。地面站能够跟踪和下载卫星的位置的数据,应用程序必须在视觉上显示卫星的位置和路径,并提供数据。 为了迎接挑战,Satnogs大量使用了3D打印技术,这些志愿者和爱好者通过3D打印技术随心所欲的实现他们的设计想法,几乎他们小小的零部件都通过3D来打印–甚至三脚架也是通过3D打印来制造的!

他们通过3D打印创造了数量庞大的齿轮和壳体,并不断的调整齿轮的设计,Satnogs团队试验了各种各样的齿轮设计,从而保证这些齿轮优良的机械性能。” 忠于开源精神,Satnogs也公布了所有设计的文件,他们希望这将节省其他卫星爱好者的大量时间。

3D打印涡轮是很大的挑战,需要不断的仔细校准和微调(层高,冷却,找平,填充设置等)知道打印出匹配的涡轮和齿轮涡杆。我们甚至尝试用丙酮ABS进行表面处理,每种尝试都会有所发现。

这些技术怪才们可能正为我们揭示低成本的3D打印与科研创作相结合的新时代呢。

(3D科学谷编译自3ders, 欢迎转载,转载请连接至www.51shape.com)

Greek hackerspace uses 3D printing to construct an open source satellite network ground station

We’ve all known that 3D printing is especially useful to quickly develop small, affordable plastic parts and components for a variety of projects. Not only does it save a lot of many to print and design these yourself, it also allows you to easy prototype and modify your parts.

However, we are constantly surprised by the new and innovative ways this function is practically applied. The latest impressive project we’ve come across is the Greek SatNOGS project, that is developing a functional, complete platform for an open source Networked Ground Station. Through this ground station, that has been developed using a multitude of 3D printed parts, the Greek team has been able to communicate with hundreds of satellites and track these in real-time.

This project began as part of NASA’s 2014 International Space Apps Challenge, an international event of mass collaboration aimed at space exploration and all its aspects, that was held on the 12th and 13th of April this year. The goal of the event was ‘producing relevant open-source solutions to address global needs applicable to both life on Earth and life in space.’ Dozens of projects all of the world participated, including the SatNOGS project based in Athens, and all could focus on a large variety of different projects.

SatNOGS participated in the Virtual Ground Station App challenge, and their challenge was to ‘develop a common antenna kit or directions and an app that can receive data transmitted from these orbiting CubeSats through ground stations around the world to create a global data network. A virtual ground station app that tracks CubeSat locations and downloads their data. The app should visually show the location and path of the satellite and provide data.

In this, they were successful. As they explained on their website, ‘for the first phase of the project we designed, built, coded, documented and successfully tested the hardware and software parts of the platform, that enabled us to real-time track and communicate with satellites.’

Since then, the Greek team of hackers, programmers and engineers have been expanding their project to provide an open-source basis for a community of Satelite tracking enthusiasts. As stated on their website, ‘We love satellites! And there are thousands of them up there. SatNOGS provides a scalable and modular platform to communicate with them.’

To realise this, they are providing open-source designs for both the bulk manufacturing of the ground stations as well as the necessary software to operate them. Impressively, all of this has been realized using existing systems. Recently they have released their second version of the SatNOGS Ground Station, that features a variety of upgrades and fixes.

Especially interesting is their extensive use of 3D printing. As they are a team of volunteers and enthusiasts, this 3D printing technology has allowed them to realise their plans without extensive investments. Indeed, virtually of their little parts and components have been 3D printed – this was even the case for their tripod!

As they revealed in their blog, a vast number of the gears and casings in their second edition SatNOGS Ground Station have been created with 3D printing: ‘Working towards vs of the Ground station Gear Assembly, the SatNOGS hardware team has experimented with various gear designs. All of them were designed and 3D printed from scratch focusing on ease of reproduction and excellent mechanical operation and properties.’

True to their open-source spirit, the SatNOGS team are also making their 3D designs freely available. They can be found here. They hope this will save other Satellite enthusiasts a lot of time, as the design and printing process was, at times, an arduous experience for the Greek team. They went on to state that:

Failing was part of the process. As you can see in the pics above, 3D printing a worm gear can be a monster of its own. After careful calibration and fine-tuning (layer heights, cooling, levelling, infill settings etc) on our 3D printer we were able to consistently reproduce worm and matching gears. We even experimented with acetone abs curing, which (based on the results we are seeing) we believe should be the default for our gears moving forward.

While printing enthusiasts might not immediately think ‘Satellites!’ when tinkering with their desktop 3D printers, this wonderfully inventive open-source project is a very cool application of this expanding technology. Be sure to check out their website! It really highlights the ground-breaking innovative power that 3D printing can bring to small, low-budget teams of creative individuals.

(3D科学谷编译自3ders, 欢迎转载,转载请连接至www.51shape.com)