以敏锐的视角、高度的聚焦、深度的剖析来推动增材制造技术等高端智造技术与行业结合的发展。6月1日,3D科学谷与中国3D打印文化博物馆合作,携手德国Fraunhofer研究机构、盖世汽车中国研究院以及国内外汽车增材制造领域的专家在2018年6月1日上海举办了AME(additive manufacturing excellence)3D打印卓越论坛系列之聚焦新能源汽车。那么在这次论坛上展示了哪些有趣的零件呢?

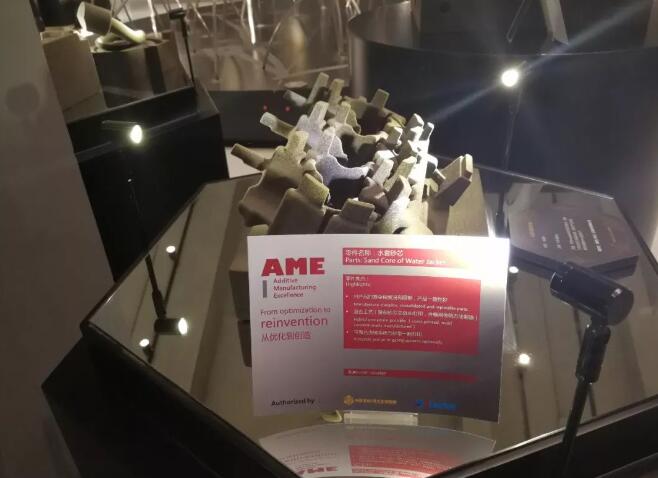

-- 水套砂芯

Sand Core of Water Jacket

voxeljet(维捷)

零件亮点:

Highlights:

对产品的复杂程度没有限制,产品一致性好

Manufacture complex, consolidated and replicable parts

混合工艺(复杂砂芯交由3D打印,外模用传统方法制造)

Hybrid procedure possible (cores printed, mold conventionally manufactured)

可整合浇铸系统与砂型一起打印

Integrate and print gating systems optionally

-- 离合器壳体砂模

Sand Mold of Clutch Housing

voxeljet(维捷)

零件亮点:

Highlights:

无模化生产,一体打印成型

Toolingless production and one-step modeling

灵活性好,不受件数、模具设计和材料的限制

High flexibility regarding number of pieces, mold design and base material

适用于单件、小批量生产

Economical production in batch sizes of one as well as in series production

-- 涡轮增压器壳体砂模

Sand Mold of Turbocharger Housing

voxeljet(维捷)

零件亮点:

Highlights:

铸造性能媲美传统工艺生产的砂模

Casting properties comparable to conventionally produced molds

铸件机械性能与传统工艺一致

Castings with production-ready properties

可整合传统铸造工艺

Integration in standard casting processes feasible

适用于所有普通合金铸造

Castable with all common alloys

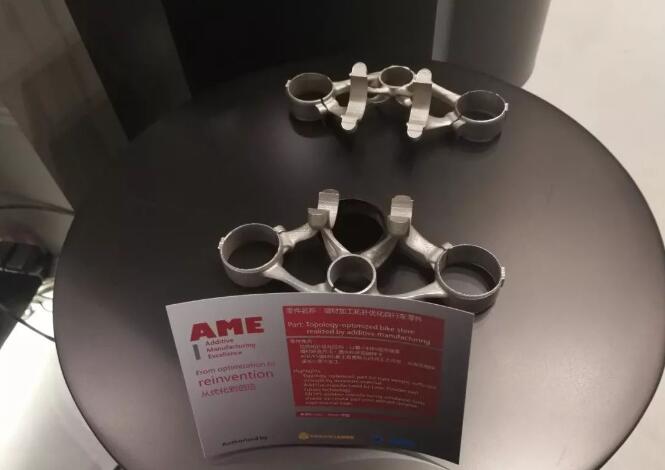

-- 增材加工拓扑优化自行车零件

Topology-optimized bike stem realized by additive manufacturing

ANSYS

零件亮点:

Highlights:

轻质拓扑优化结构,以最少材料提供强度

Topology-optimized part for light weight, sufficient strength by minimum material.

增材制造方法:激光粉床熔融技术

Additive manufactured by Laser Powder-bed Fusion technology

ANSYS增材仿真工具免除长时间工艺开发,从而实现快速成功零件加工。

ANSYS additive manufacturing simulation tools enable successful part print without iterative experimental trials.

-- 观测卫星天线支架

Sentinel Satellites Antenna Bracket

Oerlikon AM (欧瑞康)

零件亮点

Highlights:

航天应用的认证产品

Certified product for space application

比最低要求的强度提升了30%

Minimum strength requirements exceeded by >30%

高度统一的应力分布

Highly uniform stress distribution

减重40%

40% weight reduction

更低的系统成本和燃料消耗

Lowered system costs and fuel consumption

-- 喷嘴

Inconel Nozzle

Oerlikon AM (欧瑞康)

零件亮点

Highlights:

拓扑优化,实现铸造与锻造无法完成的独立

Optimized structure. Advanced single-piece component with geometry not possible through casting or machining

开放的内部通道可以在零件脱离基板前去除多余的粉末Open internal channels allow powder removal before part removal from build plate

更少的支撑材料与更快的制作周期

Reduced build time and cost with less support material

只需少量去支撑与喷砂处理,大大简化后处理流程

Simplified post-processing through with minimal support removal and bead blasting

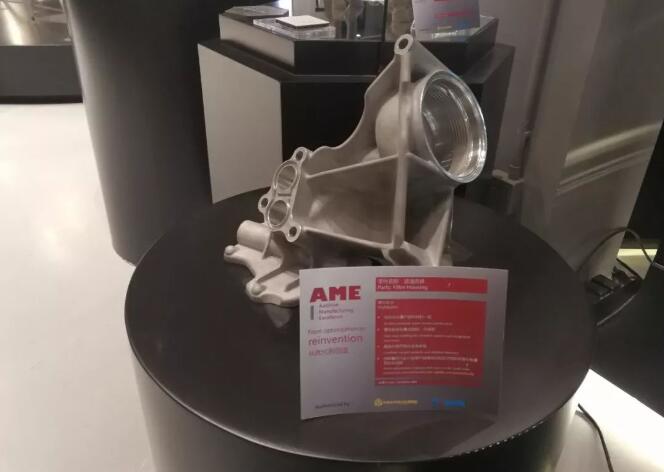

-- 滤油壳体

Filter Housing

Oerlikon AM (欧瑞康)

零件亮点:

Highlights:

铝合金和量产部件材料一致

Al alloy material, same to mass production

复杂腔体和集成结构一次成型

One-step molding for complex cavities and integrated structures

曲面和细节特征优秀体现

Excellent curved surfaces and detailed features

协助最终汽车行业用户快速和比较经济性的实现小批量测试和试制

Assist automotive industry end-users to do small scale production and trial production rapidly and economically

-- 冷却元件

Cooling Element

Oerlikon AM (欧瑞康)

零件亮点:

Highlights:

铝合金加工,极好的散热性

Made with Al alloy, excellent heat dissipating capability

风扇叶片和曲面结构传统加工耗时且不易实现,而该结构增材能实现快速加工

AM can rapidly fabricate fan vanes and curved structures, for which the traditional processes are time-consuming and hard to achieve

细节特征如风扇上的散热小孔一体成型

Detailed structures by one-step molding, such as small holes on the vanes

-- 散热器

Heat Sink

Oerlikon AM (欧瑞康)

零件亮点:

Highlights:

铜合金加工,极好的散热性

Made with Cu alloy, excellent heat dissipating capability

风扇叶片和曲面结构传统加工耗时且不易实现,而该结构增材能实现快速加工

AM can rapidly fabricate fan vanes and curved structures, for which the traditional processes are time-consuming and hard to achieve

细节特征如风扇上的散热小孔一体成型

Detailed structures by one-step molding, such as small holes on the vanes

资料下载,请加入3D科学谷3D产业链QQ群:529965687

更多信息或查找往期文章,请登陆www.51shape.com,在首页搜索关键词

网站投稿请发送至2509957133@qq.com