3D打印技术是当下人们热议的话题。目前,3D打印技术已开始应用于临床医疗。雅安人杨学彬就是这项技术用于临床医疗的受益者。此前,他从来没听过3D打印技术,手术能成功,他觉得是个奇迹。

2014年10月30日,是杨学彬在川大华西医院骨科病房呆的最后一天,他是一名颈椎管狭窄症患者。6天前,华西医院骨科采用3D打印技术,攻克了手术难题,成功为杨学彬完成了手术。据川大华西医院骨科副主任刘浩教授介绍,颈椎管狭窄症的治疗,颈后路椎板单开门椎管扩大成形术是经典手术方式。但手术中,如何精确确定椎板开槽位置成为难题,3D打印导板辅助手术成为一个有效手段。

杨学彬今年40岁,雅安人。他在工地做零工,每天需要做挑沙、码砖等工作。工作时间从早上8点到下午6点,中午可以休息一个半小时。据他回忆,今年9月23日,他正在工地干活,突然觉得很累,很疲惫。

杨学彬不清楚自己得的是颈椎病,因为之前都没有什么明显症状。他说从9月23日开始,病情变化很快。“慢慢的,腿也开始麻,走路都很困难。”10月4日,杨学彬在医生的建议下到川大华西医院治疗。手术前,杨学彬已经不能走路。“当时我觉得自己这辈子是要坐上轮椅了。”

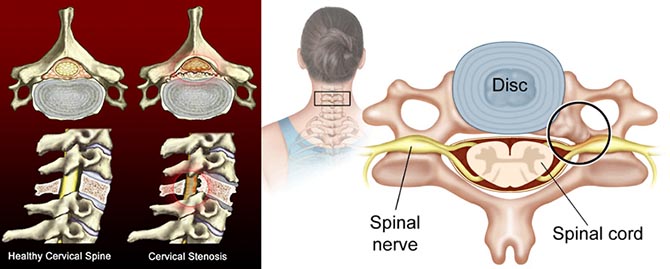

据川大华西医院骨科副主任刘浩教授介绍, 杨学彬患的是颈椎管狭窄症,导致脊髓血液循环障碍、脊髓及神经根压迫。“这个病人就是因为压迫了神经,所以会出现下肢无力,走不了路的症状。”

刘浩说:“颈后路椎板单开门椎管扩大成形术是治疗颈椎管狭窄症的经典手术方式。手术中,使用磨钻等器械在颈椎椎板的两侧切两个纵行的槽,其中一侧椎板全层切断,另一侧部分切断,然后掀开椎板,以达到使狭窄的椎管扩大的目的。”

然而,如何精确确定开槽位置是一个难题。据刘浩介绍,在临床实际工作中,都是靠手术医生的临床经验确定开槽位置。“如果开槽偏向内测则会损伤脊髓,偏向外侧则会损伤椎动脉,大脑血管将受影响。”川大华西医院骨科脊柱外科专业团队采用3D打印技术辅助手术,精确地确定了椎板开槽位置。

刘浩说,将3D打印技术运用此类手术中对患者和医学技术发展都有好处。精确椎板开槽位置将降低手术风险,对患者术后效果有好处。另外,将可以有更多的医院和年轻医生来做这项手术。“以前从业10年以上的骨科医生才能做的手术,运用这个技术做辅助,工作3至5年的医生也可以做。”

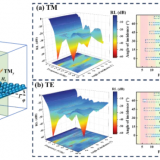

首先利用CT扫描及三维重建技术,采集患者手术节段颈椎的相关数据,再将这些数据输入计算机,编辑转化为三维模型。根据三维模型在计算机中设计出与患者椎板完全贴合的导板,通过局部解剖数据计算出最佳的开槽位置,并在导板上打孔进行定位标记。

最后,将导板的三维模型导入3D打印机制作出导板实物,一枚3D打印的导板便新鲜出炉。

在实际手术中,将打印的导板放置在手术节段颈椎的椎板上,然后通过打印导板上的定位孔在椎板相应位置进行开槽,由此,开槽的精确位置被确定,手术效果达到最佳。

来源:四川新闻网成都10月30日讯(记者刘佩佩 )

3D printing technology is becoming a hot topic recently especially at clinical medical treatment. Yang Xue-bin is one of the beneficiaries of 3D printing technology. As a patient who suffered from cervical spinal canal stenosis, before the surgery, he had never heard of the 3D printing technology, after the operation successful been done, he felt this experience was really a miracle.

Oct. 30, 2014 is the last day stay in the hospital before checking out, and 6 days ago, Yang Xue-bin, the patient of the Department of orthopedics of West China Hospital of Sichuan University, has gone through the successful operation on his cervical spinal canal stenosis. Thanks for the 3D printing technology, the Department of orthopedics of West China Hospital has successfully operate the surgery.

According to Liu Hao – the deputy director of the Department of orthopedics of West China Hospital of Sichuan University professor, “Cervical posterior single open-door laminoplasty is the classical operation method for the treatment of cervical spinal canal stenosis. The key to successfully conduct the operation is about accurately determining the position of lamina slotted. Luckily, thanks for the 3D printed guide, the operation turns out efficient and successful.

The patient – Yang Xue-bin, is a 40 years old worker who used to work on the construction site to move heavy materils everyday. He was not aware of himself to have cervical vertebra disease, because he did not suffer with apparent symptom during his daily life. But from the beginning of September 23rd, the condition changed quickly. Yang said “Slowly, my legs began to be numb, then things turn out that I became to have difficulty to walk.” In October 4th, Yang Xuebin took the doctor’s advice to ask treatment from West China Hospital. Before the operation, Yang Xuebin was unable to walk. He said “I feel that my life is going to be end up with sitting on the wheelchair.”

According to Liu Hao, the deputy director of the Department of orthopedics of West China Hospital of Sichuan University, Yang Xuebin was suffering from cervical spinal canal stenosis, and his blood circulation in his spinal cord was disordered, hence the root of the nerves has been compressed. “Due to the compression of the nerve, he suffered the symptoms of moving his legs.” Said Liu Hao.

According to Liu Hao, during the operation, they used the grinding and drilling tools to operate in the cervical vertebra lamina area to cut two longitudinal slots, they cut off one side of the lamina, and kept the other side to be partly cut off, and then they opened the lamina to operate.

However, before the surgery, how to accurately determine the slot position is a problem. According to Liu Hao, in the past years of the clinical practice, it was to rely on surgical doctors’ experience to determine the notch position. “If the cutting point is too close to the central, that will cause the injury of the spinal cord, and if the cutting point is too close to the lateral, that will damage the vertebral artery, the blood vessels in the brain will be affected.”

Liu Hao said, “In the past years, such kind of operation required doctors with more than 10 years surgeries experience in the department of orthopedics, while with the 3d printing technology to assist the work, doctors with 3 to 5 years of experience can do the operation successfully.”

In order to 3d print surgical guide, they first used the CT scanning to build up the 3d reconstruction model, then the data was input into computer, then converted into 3D printable data. During the operation, the printed guide plate was placed in the surgical area of cervical vertebral lamina, and then the doctor sloted in the corresponding position of lamina through the positioning hole on the guide plate.

51shape.com translated from: Sichuan Chengdu News . October 30th (reporter Liu Pei-pei)